In the last few months, we’ve shipped over 6500 fins across the world!

So far, these are our most impressive numbers since the launch of Boost Surfing.

As of this week, we’ve received a new shipment of 2000 fins from our factory. We will be sorting, preparing, and sending them out to all of you in no time.

Likewise, our Australian partners have been shipping orders for the past few weeks now.

Thank you for your continued support of Boost Surfing!

We're still on our way to execute pre-orders (with another 4,100 fins en route and 2,000 ready to be sent to USA) and are excited to see the new fins help our customers have more fun and get closer to their goals.

• US and Canada: 1,300 fins are scheduled to arrive to our California warehouse and be shipped right away in late August, next 2000 fins are scheduled to be sent to US warehouse mid-August (which covers all 2020 orders)

• Europe: 1,500 fins will be delivered by train to Europe by mid-September (Orders before ~ August 2020)

• Australia and New Zealand: 500 fins; Kickstarter & Indiegogo backers (Orders before ~May 2020)

• Japan: 800 fins (Orders before ~ Fab 2021)

We have been working hard on making it possible to transport our BoostSurfing electric fins to South America, South Africa, and Korea. We are currently in the process of developing an optimal shipping route that will get your order to these destinations instantly. We will keep you updated as we carry on with this project.

We have updated the Quick Start Guide and Maintenance page to provide valuable information on how to take care of your fin after it arrives.

We are working towards having ALL of the preordered fins delivered as soon as possible. However, if your surfing trip is scheduled for the near future, we provide an opportunity to you get your fins in 5-8 working days by airfreighting. Please note that there is an additional charge for air delivery.

To arrange an express delivery, please, contact us at [email protected] with your order details. Your email should include:

• Shipping/mailing address

• Order number.

The container with 2000 pieces has arrived in Long Beach port 2 days ago - Feb 26. It's going through customs, once released and gets to the warehouse we will start shipping them out.

We are working out the production schedule and next shipments for the rest of the world in the meantime.

2000 pieces finally left Shanghai yesterday and are on the way to Los Angeles. (Reason for the delay that we were told was "Crew got covid"). It should arrive in LA is Feb 22.

Quick update - we should have ~2700-2800 fins ready by the end of December, Mid January to fill in 20" container and will send that container with fast sea freight in Jan. I was told it will take 16-22 days to get to US.

It should take care of all the US Kickstarter / Indiegogo orders and early website orders.

Also before Jan 20th we plan to send some fins to Australia and Japan as well. I'll get quantities a little later.

We’ve tested 50 Fins with our customers. Almost everyone was satisfied with the experience with the Fins and you can read some of their reviews / feedback in our private Facebook group.

During the tests, we have identified one non-obvious problem that doesn’t appear often. But we found out that in some cases moisture can get inside through the motor and its wires. We designed a waterproof testing tool, which allows us to quickly perform waterproofing tests on the Fins right on the manufacturing lines. That way we can be sure every fin is tested.

Updated the jack and its closing cap. The jack itself is waterproof and is closed with the protective cap to prevent water from coming in but during riding water gets still in so then when wet copper is left to dry it gets oxidized. So we found a new coating for the jacks that should fix the issue. At the same time, we’ve improved the plug for the jack to make it more sealed.

We received all necessary certifications: CE, FCC, RCM, ROHS, TELEC and now can start mass shipping.

Received funding, which will be used to deliver all the Fins from the current batch of 12k Fins and for further ramping up the production and shipping for more stock.

The current production status:

1. We’ve reassembled 750 units, fixed all the issues mentioned above.

2. At the start of next week, we’ll be sending 100-200 Fins with Air just to make sure that all is good. Fins will be shipped to people in the order of when it was purchased.

3. At the moment we’re assembling 4800 Fins - 200 Fins a day 6 days a week. Currently, apart from 750 complete Fins, we have:

800 painted Fins

1200 in the painting queue

1800 Fins with installed antennas

1000 sets of cast plastic

2000 pre-assembled ducts with motors + 4000 sets of pre-assembled propellers

The first mass-produced batch had been shipped in September (the Fins which we shipped before were produced by our engineers at our lab) and there was an issue with that batch - our partners didn't follow one of the steps in the instructions and didn’t add enough sealant to all of the Fins, which caused leakage in some so we recalled that batch. There should be no such problem with the next batches.

The new batch of 1000 units is ready. We are flying 20 Fins from this batch to our local office in Huntington Beach, USA and some to Australia to test those right away and get the feedback asap, so if there are any issues we can solve them straight away at the factory. As soon as we confirm that everything’s fine, we will ship the rest of the batch to you.

The production is in full swing, we’re producing 500 Fins a week. From November, all the processes will be established and we will scale up the production. We will produce 2500 in November, 4000 in December and 3500 in January.

Alex, our CTO is finally getting a Chinese visa and should be flying to China next week - this is a big step for us as we had to control all the processes remotely up until now, which is why some issues occurred.

Another batch of 100 Fins are fully assembled, packed, assigned tracking numbers, and awaiting dispatch in the next couple of days from the logistics center in Hong Kong. Very important to note is that this is the batch from our Manufacturing facility. So these are the mass production units. Meaning the next batches are coming shortly after it.

The next batch of 500 Fins has already been produced and will be assembled by the end of this week, and we will immediately begin to prepare it for shipment.

At the moment, the next batch of 1000 pieces is being produced, the plastic for the remotes is ready. We expect it to be fully ready by mid-October and will start shipping orders right away.

The production of boxes is completed, they are ready and waiting at the factory.

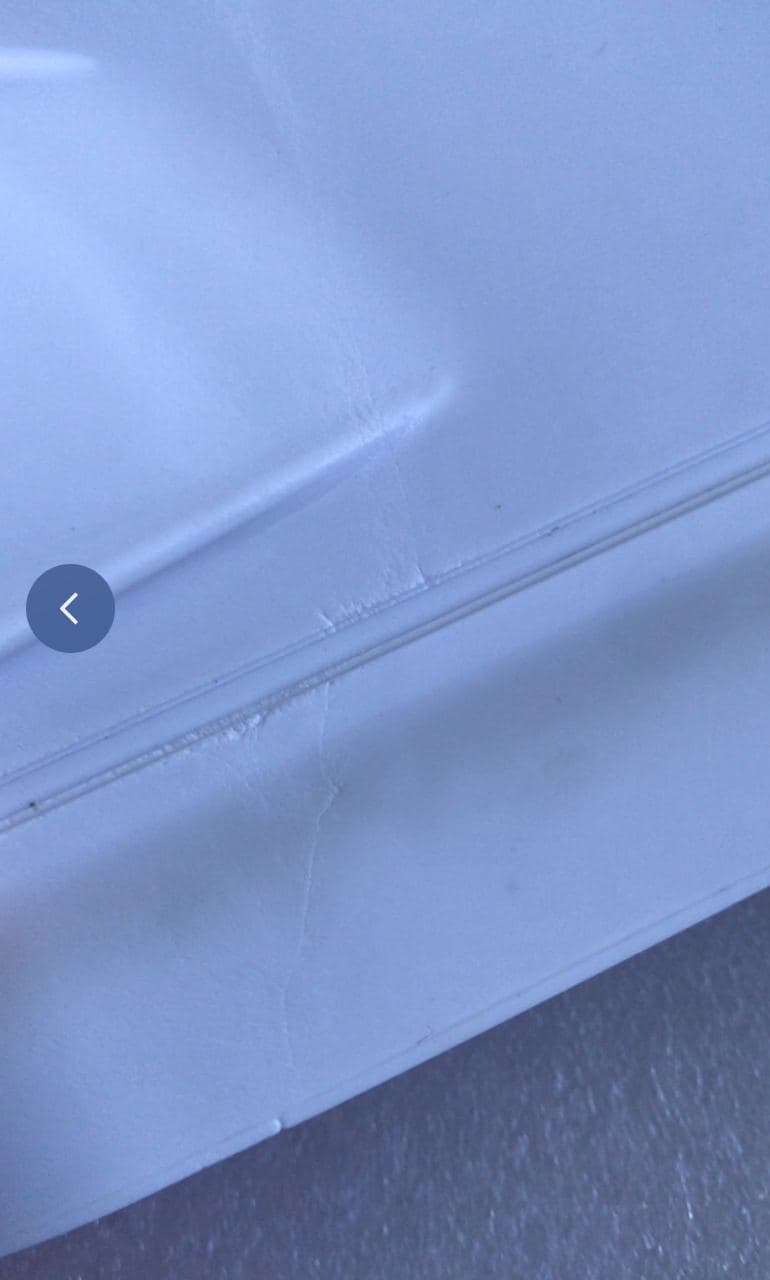

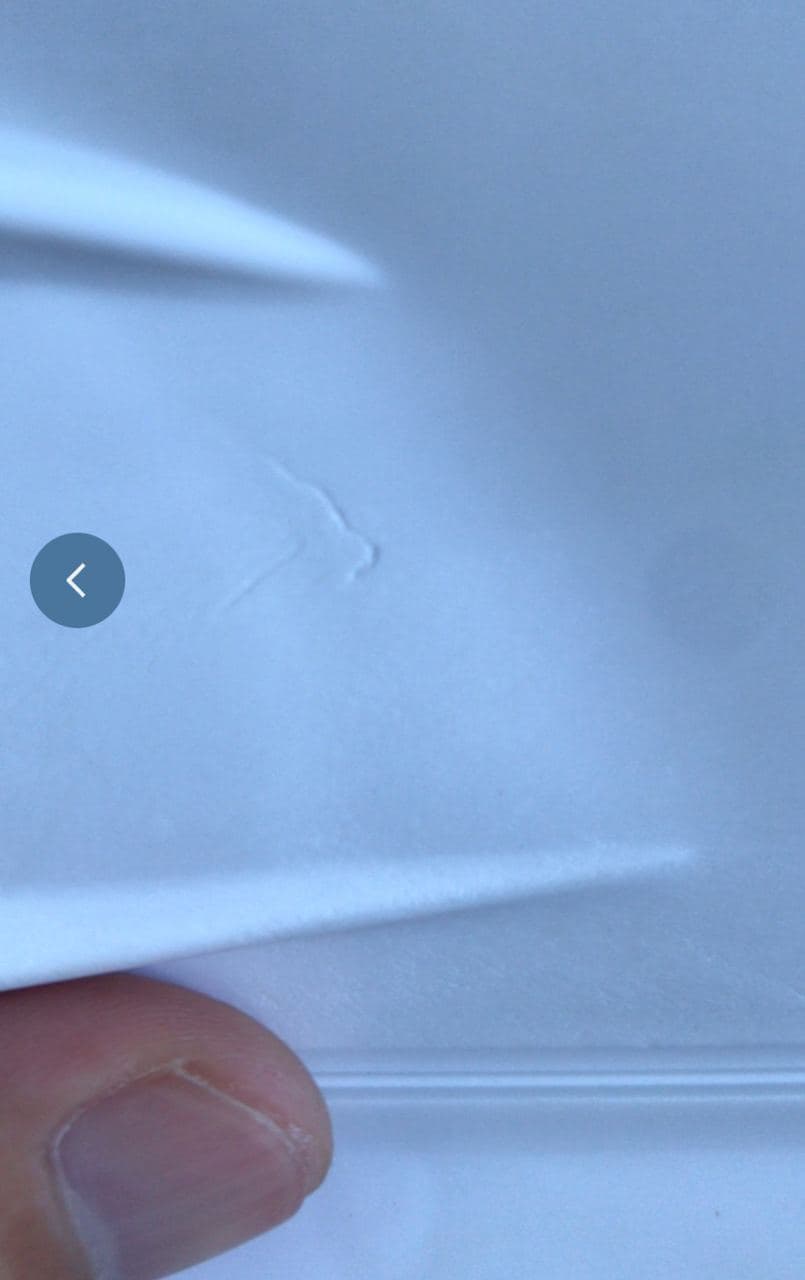

200 pieces have been slightly delayed. We weren’t satisfied with the painting results, as you can see in the photo, so we asked the manufacturer to redo them. The Fins have already been produced and painted and we can start shipping them on August 13th!

We are already producing the next batch of 2,000 units and it’s still expected to ship this month.! The remotes for this batch will be ready very soon, all the Fins will have the new firmware uploaded, and right now we are recharging 10k batteries at the factory, because they could be partially discharged while they were stored.

We have most of the adapters ready, which we will ship with the next batch.

We’ve developed the Boost Fin Leash for more security, especially when using the Fin with FCS/FCS 2 and Futures adapters, and it is available for ordering in our store.

We have received very valuable feedback from the first 75 customers that helped us pinpoint a few important moments that we had to improve in our bigger batches.

We launched the production of new remotes, which we made smaller and more convenient. These are completely waterproof and perform much better. The mass production of these remotes is already underway, 200 remotes will be ready on the 13th of July.

We are preparing the second batch of 200 Fins for shipping. 100 pieces have been painted and assembled at our factory, another 100 pieces were sent to the second factory - in order to increase the production capacity, we decided to utilize two factories, and now it is important for us to make sure that the second factory will produce and assemble the Fins up to standard.

We updated the firmware of the motherboards, which allowed us to increase the smoothness, remove freezes, increase the response speed, improve the connection between the remote and the Fin, improve the activation of boost modes as well as many other positive aspects. The new batch of Fins was delayed largely due to the fact that we were developing and testing the firmware.

We are finalizing the app - we’ve already added several pre-set modes for surfing and SUP boarding. Also, we are in the process of improving the interface and adding tutorials to the app. The new version with pre-set modes can already be downloaded from the App Store and Google Play.

Our first customers have already received their Boost Fins from the mini-batch, we are shipping them gradually, and have already shipped 30 Fins which were sent all around the world - to the USA, UK, Japan, Australia, Spain and other countries.

We’ve done performance tests on a SUP board in the ocean and received the following results: at 35% motor power a SUP board develops a speed of 4.4 km/h and covers 8 km in total on a full charge, and at 40% power the speed will be 4.8 km/h and it will cover 5 km.

We’ve conducted lots of tests with the fins in the ocean, and to save you the trouble of choosing modes in the app, we decided to offer you a set of modes for various needs and scenarios. In the app, you will find both short surfing modes - for short boosts, and long modes for SUP board: Getting to the line-up 3 min, SUP Assistance 100 min, SUP Trolling 70 min, SUP wind / current resistance 40 min. You can also adjust the short boost settings to customize the Boost Fin for you.

We have finalized and launched a small remote into mass production, with a strap from Apple, which can be worn on the wrist or forearm. The option to attach the remote control to the board will be available a little bit later.

We’ve begun shipping the first fins. At the moment we’re sending out the fins from the mini-batch of 75 pieces which we’ve assembled at our European R&D office, while the main batch for mass-production is being prepared for launch.

During May we will be ramping up our assembly processes of mass production. So we will be able to produce about 100 more units and ship them, the main aim of this stage is to make sure that the factory assembles the fins without any mistakes, and in june we will significantly scale up the production of the fins.

The final mold is ready and we launched mass production of the shells. To remind you we had to update the design to fix the issue with the antenna. We received, tested and approved the fins - they are good. Here’s a video from the production:

After that, we plan to run the production lines at full capacity and produce 7000 fins in June and 7000 fins in July. This plan is a little optimistic, but it is possible, so we will try to do our best to make it happen. We will be sending small shipments once they are ready, so we will try to ship all the orders this summer.

Some other small but important improvements: we slightly redesigned the packaging, removing excess plastic from it to reduce environmental damage. Also, we are making the final preparations - we’ve made the barcodes for the box, finalized the insert with instructions and are polishing and testing our application.

The new 75 motherboards for the remotes have been sent from the production facility and should arrive at our European R&D office in a couple of days. As soon as we receive them, our engineer will assemble the remotes and we can start shipping the first Fins.

The first 75 Boost Fins were manually assembled at our European R&D facility. The antennas proved to be very durable.

At the same time, we're finalizing the new molds and will start mass production of the Fins next week. They will be assembled with antennas according to our new specifications. In this video you can see a sample of the Fin with the attached antenna, which looks perfect. These Fins will be in the batch of 2000 orders.

This video shows the new waterproof casings for the remotes which are now ready for assembling.

Certification process is almost over, we were asked to provide a specification for one small component, which we did, so we will get the certification very soon.

We've also done the tests on the batteries to make sure they haven't been damaged or discharged waiting at the production facilities for some time and the PCBs to make sure there is no corrosion on them. Everything is good.

As for some other news, we've finalized the new straps for the remotes and produced braces for the 2000 Fins.

We also finalized the testing procedures for the Fin and its components.

We received the final Fin sample at our European R&D facility last week and it looks very good, apart from a couple of small things.

Remotes had a small issue with the signal. The engineers in the manufacturing facility decided to improve the signal and they changed the signal coding which makes the signal longer and the receiver doesn't consistently get it. Once we'd figured the issue, we started fixing it immediately. The new sample will arrive next week and we will finalize it. Other than that, everything else looks great and works perfectly.

We're already assembling the Fins at our European R&D facility manually. The biggest obstacle that stops us from beginning mass production is the ability to repeatedly glue the antenna perfectly into the shape of the Fin without leaving any glue stains. We figured out how to do it manually but it's a very long process and the factory won’t be able to replicate the process. We purchased several machines which should arrive early next week and we will record the instructions for our partners at the production facilities on how to do the process.

We've already sent our Fins to the certification office a week ago, they told us that it should take about 3 weeks, but usually, it takes less time to get all the certificates. Soon we will be able to produce a lot of Fins and finally start shipping them.

The 75 units are at our European R&D office, they have arrived partially assembled and we're currently assembling them, but we had to wait for some parts that had not arrived on time. After we assemble them, we will ship them and then we will start the mass production of the next batch of 2000 Fins which should be ready and shipped around April.

75 Fins have been painted, assembled and packed. Currently, they are on their way to our European R&D department where they will be thoroughly checked and then shipped from to our customers.

.gif)

.gif)

PCBs for the Pro remotes are ready, the remotes are assembled.

New plastic casing samples for the original remotes are ready, currently testing them to finalize.

100 Fins are pre-assembled. They’ve been sent for coating, which will take 5-7 days, and after that, they will be fully assembled.

.gif)

Continuing work on the original (small) remote. Finding the best solution to ensure the waterproofness of the casing.

The casing for the PRO remote is ready, silicon buttons are ready, performed tests on the batteries, waiting for the PCBs to assemble them.

Making preparations for the certification of the Boost Fin.

2000 main PCBs (of the Fin) are ready.

Plastic housings for 100 Boost Fins are ready. Next week they will be painted.

Finalizing housings for the custom (original) remote, we did lab waterproof tests on them which had been successful. Will need to do open water tests to make sure they are fully waterproof.

Another batch of 2000 Boost Fin motors is ready.

New mounts and charging jacks are ready.

Finished the production of 100 PCBs for a custom (small) remote.

Straps for the remotes are ready.

Finalized the second tray for the boxes and the attachment of the trays to the lids. The first batch of 100 boxes are ready.

Finalized the fitting of the antenna, doing final tests of the coating of the antenna.

Doing some corrections on the adapters’ molds - after the tests we had to increase the thickness of the screws and add the nuts into all the adapters to increase their resistance.

Finalizing the boxes, testing several EVA inserts options, testing the attachment of the trays to the lids.

Began the production of the plastic for the first batch of 100 Boost Fins.

All the parts for the first 100 Boost Fins (fin body, duct, ring, propeller adapter, propeller, rubber pads, spacers, antennas, screws, battery, chargers, motors, ESC, screwdriver, longboard adapter’s insert, nut, cap, FOAM parts, rubber gaskets, jack) will be ready on 13.12. After that, it will take 5-7 days for the painting process.

Finishing all the necessary corrections of the mold (the charging jack, the cap for the charging jack and the groove for the antenna), the final shot will be ready on the 13th Dec.

The first prototype of the original (custom) remote is ready, we’ve inserted the PCB in it and are testing its waterproof qualities.

Waiting for the final shot of the plastic mold (after we had to make slight changes due to using a different jack). Then we’ll test it and launch it into mass-production if everything is right.

Continuing work on the original remote, first prototypes will be ready next week.

Preparing to begin the mass production of the Pro remote.

We’re making new copper jacks with nickel plating for the first 2000 units.

The boxes for the first 100 Fins are in production, we’ve had to make a separate mold for the second tray so that the product fits more securely into the box. We are now waiting to test and finalize them.

Making final corrections to the Boost Fin mold, because we had to make changes due to changing the jacks to more waterproof ones.

We’ve tested the Pro remote and finalized it.

Ordered plastic casing kits for the Pro remote from Japan, they’re on the way to our production facilities.

We received test shots from the new adapter molds (the longboard one is ready, working on the rest of the adapter molds).

We launched mass production of the main PCB (motherboard of the fin).

Prototyping the new plastic casing of the original custom remote and PCBs for the first 100 remotes.

Searching for a better charging jack solution - the one that we currently have doesn’t meet our waterproof standards, so we are checking other options.

Inspecting the new plastic casing sample. If all is good, we will assemble the first 100 fins (all the other components for them are ready) and will ship those in December.

2000 additional units, which we’ve ordered last week, are in the process of production, including additional screwdrivers, batteries, modules, and other components.

Samples of original custom remotes are on their way to our CTO Alex in Bali and to our European R&D office for tests. After we receive their feedback, we can begin the assembling.

We are waiting for strap samples for the Pro remotes and will send them to our CTO for tests. At the same time, we’ve ordered 2240 casings for those remotes, so when we have the PCBs and casings ready, we can assemble Pro remotes.

Finishing work on the boxes, they should be ready at the end of next week.

6 new addons will be ready before the end of the month - the Boost Fin case, a safety bumper, a safety leash, a car charger, a Pro version of the remote and a snorkelling adapter, they will be available in our online store and you can add those accessories to your order.

We’ve ordered 2000 units of improved (pro) remotes. At the same time, we’re making custom original remotes, working on the mold for it, waiting for quotas and a test sample. This remote can be worn on a wrist, a shoulder or attached to a board.

We found a manufacturer of a car charger, waiting for their quota and a test sample.

Final updates to the mold that will have the new antenna should be ready in 1.5 weeks.

The test sample of the safety leash is ready, we are waiting for it to arrive to test it.

The fin add-ons - safety bumpers - are ready.

The longboard adapter mold had been approved and launched into mass production, the molds for all the other adapters are being approved.

We have found the right glue and the thickness of the antenna to finally launch the mass production of the fins.

We’re waiting for the quotes from the factories for original (simple) remotes, the casing will be customized to increase waterproof qualities. After we receive the quotes and approve the production, we will finalize the silicon strap for it.

Customizing the jack for the fin, our R&D facility in Europe and CTO in Bali are working on the final version of the jack.

Continuing to work on the antenna. Next week our employee will be at the production facility to determine the issue during the production with the outside positioning of the antenna. Additionally, we’re testing an option of installing the antenna inside the fin. After we find a solution, we can finalize it and start producing the mold for the fin.

Our CTO Alex had tested the mass-produced sample of the fin and was satisfied with the results - it produces enough thrust, works perfectly with the app, provides good battery life, the casing is very durable.

We have tested original remotes and custom prototypes and they both showed great results. We are beginning the negotiations with the remotes producers about a casing solution.

Finalizing a prototype of the box for the adapters.

Alex had tested the new jack in saltwater and found the solution for ensuring its water resistance.

Continuing work on the antenna, trying out different installation solutions. When the issue with the antenna is resolved, we can fully assemble the first 50 fins.

We’ve tested button PCBs (motherboards) and PCBs of the Fin and now we’re ready to launch them into mass production - this was the major delay and now it’s finally behind us.

Finished a second tray for the box (after creating an additional mold) - we’re testing it now so it fits in the box perfectly, after this, we can start mass-production of the boxes.

Changed the color and finished the mold for the ring.

Finalizing the antenna. The material of a small element - a clamp - in the antenna was changed from iron to copper for greater salt-water resistance.

Working on additional components - bumpers for the fin.

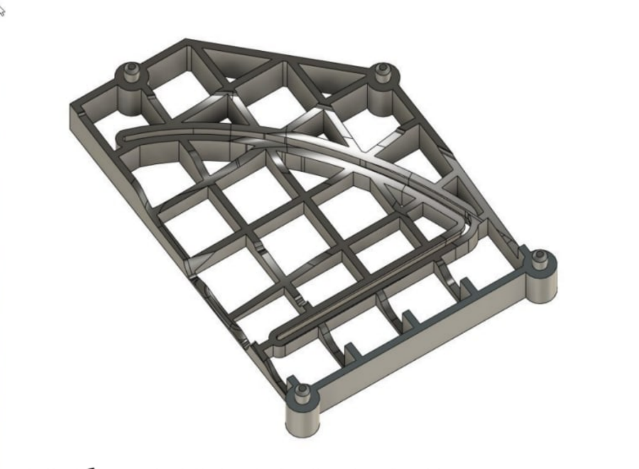

Developed a set of inserts for the fin which will be used to fill in some cavities in the fin to exclude/minimize water ingress.

Dmitri, CEO of Boost Surfing, received remote prototypes for tests in the sea and waiting for the mass-produced Boost Fin sample.

Custom made remotes have arrived at our R&D facility, we need to test the code transfer protocol we declared, the stated range of codes, the required IP67 sealing, the required power of the expected signal. After the tests, they will be sent to our CTO and CEO for final tests and approvals.

A test batch of PCBs has arrived at our R&D facility in Europe, they were tested in the lab, we only need to test them in saltwater before we can launch mass production of PCBs, they’re on their way to Bali and the USA for saltwater tests.

Testing PCBs in Bali, if the tests are successful, we will launch mass-production of PCBs

The Boost Fin sample with the new PCB has been lab-tested in our production facility in Europe, now it’s on the way to Dmitri (CEO) for additional testing in the USA

Conducted durability testing of the mass-produced Boost Fin sample in Bali (full video available here)

Finalizing the box and its contents (waiting for the final decision on the remote to make the most durable and convenient fixing tab).

Made the first trial mass-produced batch of PCBs (waiting for the samples to test them)

Collected the plastic for the first trial batch (50 pieces).